Semiconductor & Electronic Adhesives

Semiconductor & Electronic Adhesives

Technical Literature

- Underfill Epoxy

- Glob Top (COB) Encapsulation

- Underfill and Glob-Top Encapsulation

- Die Attach & TIM’s for CPU

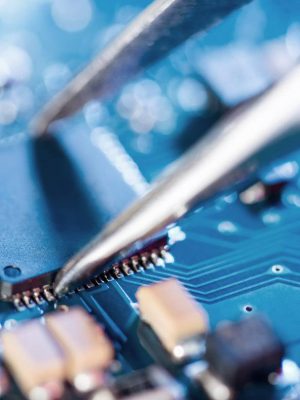

- Substrate and Component Attach

- Flip-Chip and BGA Underfills

- Die Attach Adhesives

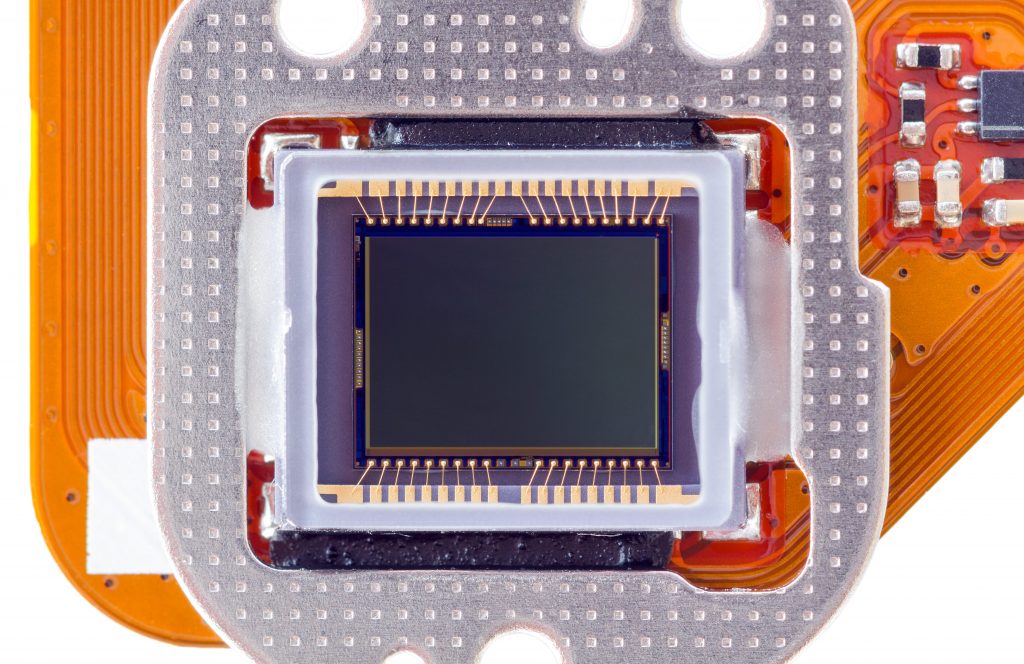

Die Attach Adhesives

Die Attach Paste Adhesives

AIT offers some of the most advanced Die Attach paste adhesives engineered to improve long-term reliability, rapid inline curing, long pot-life, viscosity and thixotropic control for fast automated dispensing and manufacturing. Some of the following representative products have a demonstrated record of more than 20 years of reliability for military and aerospace applications.

| AIT Part No | Characteristics | Electrical Resistivity (Ohm-cm) | Thermal Conductivity (Watt M-0C) | Die-Shear (PSI) | TG (°C) | Viscosity / Thixotropic Index |

|---|---|---|---|---|---|---|

| EG8020 |

|

<4x10-4 | >5.7 | >1,800 | 50 | 150,000(cps@ 0.5 rpm) |

| EG8050-LV |

|

<4x10-4 | >7.9 | >1,500 | -20 | 129,000(cps@ 0.5 rpm) |

| EG8050 |

|

<4x10-4 | >7.9 | >2,000 | -20 | 190,000(cps@ 0.5 rpm) |

| ME8155 |

|

<4x10-4 | >7.9 | >2,000 | -20 | 354,000(cps@ 0.5 rpm) |

| ME8452-A |

|

<4x10-4 | >7.9 | >2,000 | -20 | 255,000(cps@ 0.5 rpm) |

| ME8456 |

|

<4x10-4 | >7.9 | >1,000 | -20 | 130,000(cps@ 0.5 rpm) |

| ME8456-00 |

|

<4x10-4 | >12.5 | >1,200 | -20 | 60,000(cps@ 0.5 rpm) |

| ME8512 |

|

<4x10-4 | >7.9 | >1,200 | 50 | 15,000(cps@ 0.5 rpm) |

| ME8550-DA |

|

<1x10-3 | >7.9 | >1,000 | -55 | 40,000(cps@ 5 rpm) |

| ME8630-DA |

|

<4x10-4 | >8.6 | >2,400 | 80 | 8,000(cps@ 5 rpm) TI >4.0 |

| ME8630-RC |

|

<5x10-4 | >8.6 | >2,400 | 80 | 15,000(cps@ 5 rpm) TI >4.0 |

| ME8650-DA |

|

<4x10-4 | >3.6 | >1,900 | -40 | 8,000(cps@ 5 rpm) TI >4.0 |

| ME8650-RC |

|

<5x10-4 | >7.9 | >1,500 | -20/-50 Minor | 18,000(cps@ 5 rpm) TI >4.0 |

| ME8850-DA |

|

<5x10-4 | >7.9 | >1,000 | -20/-50 minor | 10,000(cps@ 5 rpm) |

| MC8880 |

|

<5x10-2 | >9 | >2,500 | 240 | 65,000(cps@ 5 rpm) |

| Vitrobond AG806-2 |

|

0.0005 | 60 BTU/in | 2400 | 70 | 30,000 – 40,000 |

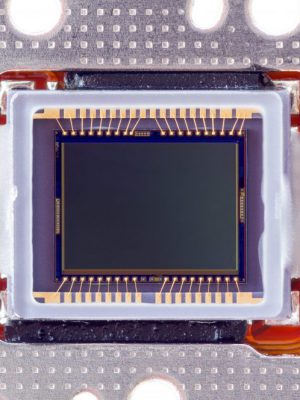

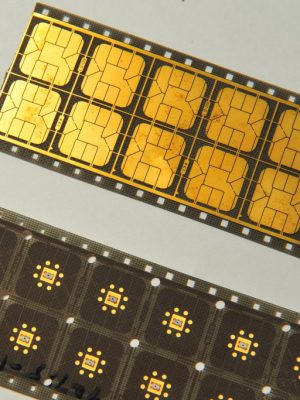

Die Attach Film Adhesives

DAF (Die Attach Film) and DDAF (Dicing Die Attach Film) Adhesives

PROVEN RELIABILITY

Die-Attach film (DAF) adhesive has become popular and mandatory when stack chips are used to accomplish larger capacity in 3-D packaging of flash memory devices. The push now is for an even thinner insulating die-attach adhesive that can properly handle interfacial stresses in stacking chips with bond-lines as thin as 8-10 microns or less to help mobile devices to achieve even lower profiles.

In addition to offering a thinner bond-line for stacked chip devices, film adhesives that are properly engineered for die-attach provide several advantages over traditional paste adhesives for almost all semi-conductor devices:

- By eliminating the paste dispensing requirement of low viscosity, AIT produces DAF film adhesives with proper melt-flow and bonding characteristics with engineered molecular structures to manage stress, thermal stability and moisture absorption and sensitivity with unparalleled performance

- By laminating the DAF film adhesives with controlled thicknesses from 10 microns, AIT DAF adhesives melt-flow at temperatures around 80°C and are thus ambient storable for shipping and handling for one year at ambient temperature before or after dicing

- AIT is also one of the first to provide proven DAF adhesives that are electrically conductive for power devices in the thickness of 20 microns

- AIT is also one of the first to provide thermally conductive DAF adhesives that are electrically insulating but thermally conductive with years of proven success manufacturing thicknesses of 20 microns.

- AIT DAF is also engineered to melt-flow and bond onto substrates at a temperature of 125-175°C with minimal pressure of around 5 psi and continue for full cure at the same temperature without applying pressure. Unlike paste, the die position will not shift, thus allowing ultra-precise packaging needed in multi-chip modules (MCM) or SiP (System-in-package).

In addition to offering a DAF adhesive with unparalleled performance in managing interfacial stresses even at low bond-line thicknesses, ultra-low moisture-temperature sensitivity, and thermal stability, all with high enough glass transition temperature of 175°C and beyond in enabling high productivity of wire-bonding up to 250°C, AIT DAF adhesives also feature more common properties used in worldwide production:

- RoHS and REACH compliant

- Availability of width for 450mm and beyond for all thicknesses from 10-micron thickness and with option for pre-laminated onto dicing tape (DDAF) with standard, UV, and/or thermal releases

- Manufactured in a clean room environment with a scalable capacity of more than 10 million square ft per year in the United States.

| AIT Part No | Characteristics | Electrical Resistivity (Ohm-cm) | Thermal Conductivity (Watt M-°C) | Die-Shear (PSI) | TG (°C) | Film Thickness |

|---|---|---|---|---|---|---|

| ESP7660-HK-DAF |

|

>1×1014 | >0.8 | >4,000 | 175 | 10 µ20 µ40 µ |

| ESP7666-HK-DAF |

|

>1×1014 | >1.8 | >2,000 | 175 | 20 µ40 µ |

| ESP8660-HK-DAF |

|

<4x10-4 | >8.0 | >3,000 | 175 | 20 µ40 µ |

| ESP8450-DAF |

|

<4x10 -4 | >8.0 | >2,000 | 90/-50 | 20 µ40 µ |

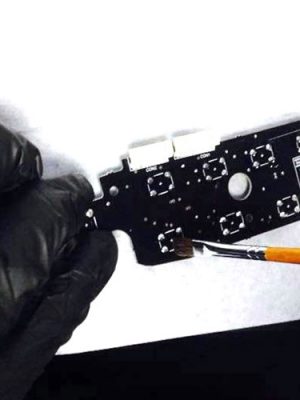

One Component Heat Cure Epoxy

Glob Top Epoxy Encapsulant

| Product No | Characteristics | Application | Viscosity (cps @ 25°C) | Cure Profile |

|---|---|---|---|---|

| Vitrobond EC 108 |

|

Glob Top | 150’000 | 130°C @ 1 Hour |

| Vitrobond EC 1002 |

|

Glob Top | 70’000 – 90’000 | 90°C @ 30 Minutes |

| Vitrobond EC 5640 |

|

Glob Top Potting & Encapsulation |

42’000 – 65’000 | 100°C @ 30 Minutes 80°C @ 60 Minutes |

| Vitrobond VC 108-1 |

|

Glob Top | 72’000 – 95’000 | 100°C @ 5 Hours |

| Vitrobond EN 484 |

|

|

Thixotropic | 100°C @ 3 Hours |

| Vitrobond EN 640-T5 |

|

Glob Top | 72’000 | 130°C @ 2 Hours |

Heat Cure Bonding Epoxy

| Product No | Characteristics | Application | Viscosity (cps @ 25°C) | Cure Profile |

|---|---|---|---|---|

| Vitrobond HEM 495 |

|

Encapsulation Casting & Potting |

40’000 | 130°C @ 1 Hour |

| Vitrobond HEM 405 |

|

Potting Sealing |

22’000 | 100°C @ 40 Minutes |

| Vitrobond JD 322 |

|

Bonding components Sealing |

128’000 – 195’000 | 100°C @ 30 Minutes Or 80°C @ 60 Minutes |

| Vitrobond EC 401 |

|

Bonding Sealing |

48’000 – 50’000 | 140°C @ 30 Minutes |

| EW JC 349-4 |

|

Bonding Sealing |

71’000 – 82’000 | 140°C @ 40 Minutes |

| EW JC 564-34 |

|

Bonding Sealing Encapsulation |

25’000 – 60’000 | 100°C @ 60 Minutes |

| EW JC 564-65 |

|

Bonding Sealing Encapsulation |

42’000 – 65’000 | 80°C @ 60 Minutes |

| EW JD 380-8 |

|

Bonding Sealing |

241’000 – 363’000 | 150°C @ 60 Minutes |

| EW JD 661 |

|

Bonding Sealing |

15’000 – 23’000 | 60°C @ 60 Minutes |

Surface Mount Epoxy

| AIT Part No | Characteristics | Application | Viscosity (cps @ 25°C) | Cure Profile |

|---|---|---|---|---|

| EW JC 711-13 |

|

Surface Mount Adhesive | 80’000 – 150’000 |

|

| EW JC 711-19 |

|

Surface Mount Adhesive | 52’800 |

|

Underfill Epoxy

New Generation of Ultra High Tg Underfill

(with Glass Transition of Over 240°C for Ultimate Flip-Chip and Component Stress Management)

Liquid Underfills with Ultra-high Glass Transition (Tg):

- Balancing these modified cyanate ester underfills that cure to much higher glass transition temperatures and the stress absorption.

- Outstanding thermal conductivity and low thermal resistance afford better thermal dissipation from powerful chip to both side of the microelectronic package.

- Proven in use for the most stringent military applications

High Melt-Flow Film Underfill for FOW:

- Outstanding melt-flow and wetting to flow-over-wire for stack-chip applications

- Ability to cure at lower temperature from 100-150°C for lower interfacial stresses

- Ideal for large area stack-chip and module

- Preform with specific thickness accommodates the flip-chip or ball-grid-array parts with preformed cut-outs for interconnections allowing the film adhesive to flow and encapsulate for protection

| Product No | Characteristics | Application | Viscosity (cps @ 25°C) | Cure Profile |

|---|---|---|---|---|

| EW JC 823-3 |

|

BGA & CSP Underfill | 550 – 850 |

|

| EW JC 823-6 |

|

BGA & CSP Underfill | 2’500 – 4’000 |

|

| EW JD100-1 |

|

BGA & Flip Chip | <20’000 |

|

Underfill Liquids and Film Adhesives:

| FUNCTION | AIT PART# | THERMAL, ELECTRICAL, & other RELEVANT PROPERTIES |

|---|---|---|

| Stress and Thermal Management | MC7866-UF |

|

| Stress and Thermal Management | MC7863-UF |

|

| Stress Management | MC7686-UF |

|

| Flow-Over-Wire Underfill Film Adhesive | ESP7660-FOW |

|

| Flow-Over-Wire Underfill Film Adhesive | CXP7860-FOW |

|

| Preform Underfill for Thermal and Stress Management | CXP7686-UF |

|

| Preform Underfill for Thermal and Stress Management | ESP7666-FOW |

|